On Demand Webinar

Featured

Webinar – Navigating The Digital Transformation Journey With Dfmpro

Digital transformation is a significant trend in manufacturing companies and is a journey that requires new, automated ways to leverage digitized information. It speeds up research and development, improves manufacturing processes, and reduces various costs of the product design lifecycle.

Webinar – Increase Agility in Product Design Iterations

Explore the symbiotic relationship between Design For Manufacturing & Digital threads. Discover how technologies in the DFM space offer real-time insights, facilitate early issue detection, optimize prototyping and testing, and empower data-driven decision-making. The integration of DFMPro will also help organizations achieve agile targets faster.

Webinar – Design for Excellence from Inception

Watch this webinar recording and learn the correlation of DFX and digital transformation, design for excellence concept in detail, sustainable design through manufacturing strategy and how early DFX/DFM creates positive impact on design.

Unlocking Efficiency: Mastering Design for Assembly in Manufacturing

Watch this webinar recording to learn essential Design-for-Assembly guidelines and see how you can easily automate them using HCL DFMPro and configure the DFM review process in your organization so that you don’t miss a single design guideline and design your product with confidence.

DFX Strategy Improves Program Performance & Digital Transformation

Learn how to drive digital transformation with DFMPro, train the workforce on digital technologies and create a digital culture, achieve higher margins, improve time to market and product quality through optimized manufacturing and assembly.

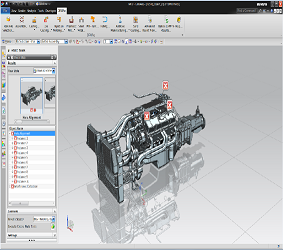

Easy and Powerful Design for Manufacturing Software for CATIA V5

DFMPro is an easy-to-use Design for Manufacturing (DFM) solution, fully integrated inside CATIA V5 that can identify & correct potential downstream manufacturing issues leading to reduction of cycle time and, in turn, resulting in high-quality products with lower product development costs. Watch this video to understand how you can run DFM checks at the click of button plus edit and update your part designs in the .CATPART and .CATPRODUCT environment.

Design for Manufacturing: A Critical Digital Transformation Element

Digital transformation is a significant trend in manufacturing companies and requires new automated ways to leverage digitalized information. While technology is available for implementing a model-based enterprise (MBE) strategy, most companies still use drawings and various siloed repositories as their sources of truth, thus breaking the digital thread.

Plastic part design guidelines every designer should follow

Watch this webinar to learn important design for manufacturing guidelines for designing Injection molding parts and see how you can easily automate and configure the DFM review process in your organization so that you don’t a miss a single design guideline and design with confidence.

Sheet metal design guidelines every designer should follow

Watch this webinar to learn important design for manufacturing guidelines for designing sheet metal parts and see how you can easily automate and configure the DFM review process in your organization so that you don’t a miss a single design guideline and design with confidence.

Designing for Manufacturability: How Alcon saves time and reduces cost with Creo and DFMPro

Learn from Alcon a pioneering medical manufacturer of eye care components on how they have achieved early visibility into the manufacturability and could save time to market and reduce the product cost with DFMPro and Creo.

Dealing with Manufacturing-Skill Gaps (Webinar hosted by engineering.com)

Learn how HCL’s DFX platform uses knowledge based rules to relieve downstream bottlenecks. Webinar focusses on key topics like manufacturing skills gap refortification, manufacturing for the next generation (with upfront DFM) and how to move forward to make a difference using one of the best tools.

Increasing Value of Design for Manufacturing in the Post-COVID World

SME presented the key results from the survey it conducted on ‘the impact of Covid 19 on manufacturing industry’ on more than 700 manufacturing professionals to understand how their companies will begin to recover past COVID 19. It includes live survey as well. Webinar elaborates on key points like what are the various Operational challenges for A&D industries due to COVID, 3 Key imperatives for design engineers in A&D organizations etc.

Incorporating Value Engineering Right at the beginning of Design Cycle

The webinar discusses product cost types, value engineering concept and why it is important to incorporate value engineering at the initial design stage while developing a product. Webinar also explains how DFMPro, a CAD integrated design for manufacturing software will help incorporate value engineering in design stage.

How Poor Selection of Materials, Design, Tooling, and Design Errors Affect the Aesthetics of Plastic Parts and What Designers Need to Know About the Science of Color and Appearance

Learn the points design engineers need to know about science of color and appearance and how poor selection of material, design, tooling and design errors affect the aesthetics of plastic parts.

Automotive Plastics: Automate your way to efficient and high-quality Plastic part design with HCL’s powerful DFX solution

Learn how you can benefit from an automated DFX solution integrated into the CAD systems for best quality Injection Molded Plastic part design, challenges in automotive plastic part design, case study on how a small missed radius led to downtime of the manufacturing line for an automotive supplier and endless possibilities with DFX platform.

How HCL’s DFX Platform is Bringing in a Seismic Change to Efficient Design and Manufacturing

This webinar will enable you to deliver quality designs faster for manufacturing, implement Design to Cost mindset at design stage with new DTC module in DFMPro, implement a cultural change to look at Design, Manufacturing and Cost as one single challenge, deploy excellent trace-ability into a model’s health with powerful analytics solution, support seamless collaboration throughout the product lifecycle and Learn how to capture and disseminate the industry best-practices and knowledge and brings in standardization across the organization.

Connected PLM enables better and faster product lifecycle decisions

Joe Barkai, a renowned industry analyst discusses a connected product development process that leveraged data form connected devices and the connected enterprise. He will discuss the role of PLM software and design and analytic tools such as DFX tools to curate rich context to drive analytics and enhanced decision-making processes.

How design errors show up as tooling, processing, materials and abuse issues

For a plastic part or assembly to perform as expected, proper consideration must be given to material selection, part design, tooling, and processing using a holistic approach. In a lot of instances, desi-gn errors are mistaken as tooling, processing and material issues. Design errors are even sometimes misclassified as customer abuse.

Design for manufacturability webinar with DFMPro and Siemens NX

Learn the key aspects of DFMPro that aim to make life easier for designers and reviewers, explore relevant case studies that highlight how DFMPro facilitates continuous process improvement through knowledge capture and reuse, how to tackle today’s challenges of faster time to market with optimal cost and high quality product.

How two manufacturing companies implemented design for manufacturing software and what they have learned

Joe Barkai explores the benefits of manufacturing verification tools as experienced by two manufacturers of highly complex equipment from the medical imaging and semiconductor fabrication industries. He will explain the motivation of these manufacturers to explore DFM tools and the benefits they have realized.

How to enhance productivity and maximize returns with DFMPro for NXTM

Learn key aspects of DFMPro that aim to make life easier for designers and reviewers, Explore relevant case studies that highlight how DFMPro facilitates continuous process improvement through knowledge capture and reuse and How to tackle today’s challenges of faster time to market with optimal cost and high quality product.

Tolerance stackup analysis simplified

With Geometric Stackup you can experience just how easy it is to perform 1-D tolerance stackup analysis on complex parts and assemblies and achieve maximum part interchangeability and improved manufacturability of designs- all without having the know-how of dimensional engineering and complex formulas. View the recording to learn more.

How design errors show up as tooling, processing, materials and abuse issues

For a plastic part or assembly to perform as expected, proper consideration must be given to material selection, part design, tooling, and processing using a holistic approach. In a lot of instances, design errors are mistaken as tooling, processing and material issues. Design errors are even sometimes misclassified as customer abuse.

Addressing cost right at design stage how design engineers need to take charge

This webinar looks at the various aspects of cost and provide an overview of the typical current approach and how it is handled in organizations at various levels. The webinar will also demonstrate how early visibility of downstream issues in manufacturing and resulting additional costs will help design engineers.

How two manufacturing companies implemented design for manufacturing software and what they have learned

Joe Barkai explores the benefits of manufacturing verification tools as experienced by two manufacturers of highly complex equipment from the medical imaging and semiconductor fabrication industries. He will explain the motivation of these manufacturers to explore DFM tools and the benefits they have realized.

How to enhance productivity and maximize returns with DFMPro for NXTM

Learn how DFMPro facilitates continuous process improvement through knowledge capture and reuse and how to tackle today’s challenges of faster time to market with optimal cost and high quality product.

Design for Six Sigma: designing for robust plastic parts

Know the Design for Six Sigma philosophy and best practices and tools for its incorporation into new plastic product development. It will help you understand DFSS concept and popular methodologies such as DMAIC and DMADV. Also, you will learn how to use DFSS Methodology in early part of plastic product design lifecycle and applying DFSS techniques and tools such as DFMPro for successful DFSS implementation.