Whitepapers

Featured

Cost based design- a fallacy?

Learn how the strong design foundation can be lead. Also, learn how attention to designing for performance that addresses all the areas of – materials, design, tooling, and processing, based on established rules and reliable data will lead to optimized costs.

Special Considerations in Designing Medical Products

This whitepaper looks at the key considerations when designing injection-molded medical devices. It also looks at how HCL DFMPro helps reduce costs and shorten the time to market right at the initial design stage.

Incorporating Value Engineering Right at the beginning of Design Cycle

This paper discusses different types of product costs and why it is important to incorporate value engineering at the initial design stage while developing a product.

How Poor Selection of Materials, Design, Tooling, and Design Errors Affect the Aesthetics of Plastic Parts and What Designers Need to Know About the Science of Color and Appearance

This paper discusses the points design engineers need to know about science of color and appearance and how poor selection of material, design, tooling and design errors affect the aesthetics of plastic parts.

Key considerations for successful new product development

Product design and development life cycle have been gradually compressed. This, in turn, has increased schedule pressures on the development team. Organizations should look for continuous process improvement to increase overall team efficiency and productivity.

Design for performance

This whitepaper throws light on how to identify and correct Design for Performance related issues early in the design cycle.

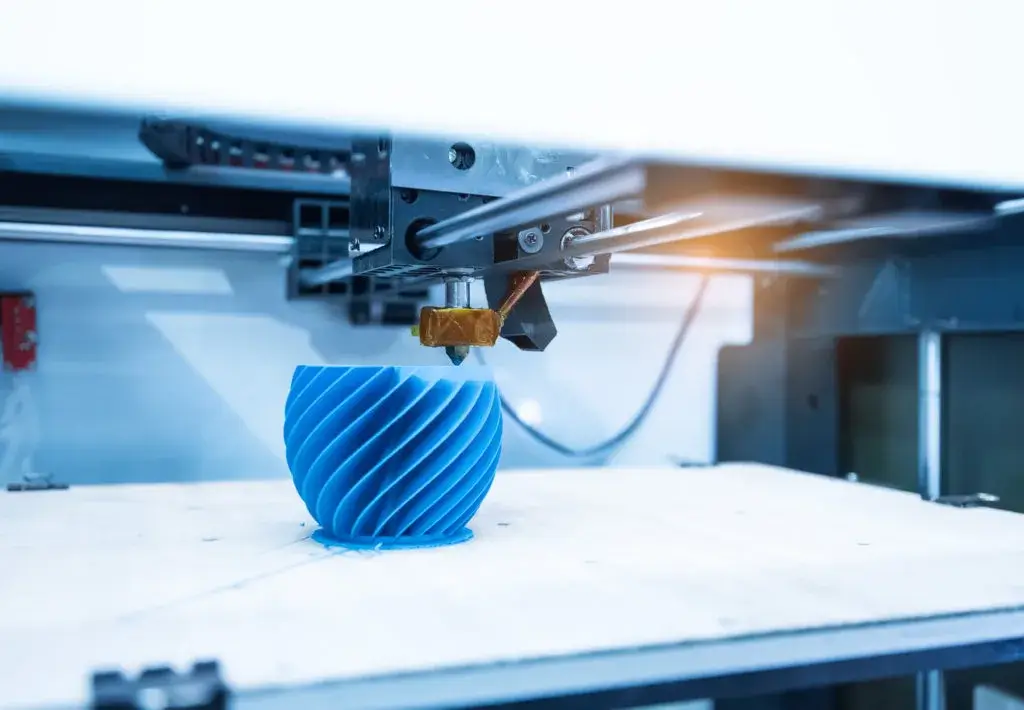

Design for additive manufacturing

There are several factors that are to be considered at the design stage for effective manufacturing of parts using additive manufacturing. Few such design issues in additive manufacturing are discussed in this paper.

The other side of design for assembly

Assembly level constraints need to be satisfied before the design can move downstream. This white paper will go through the various assembly level issues, which need to be tackled by various organizations on a regular basis.

Why and how of DFM review automation

A DFM review automation tool helps in identifying areas in a design that are difficult, expensive or impossible to manufacture. It eases and reduces errors in the design validation process. Learn more in this whitepaper.

A new approach to design and manufacturing collaboration

The benefits of cost and time savings using effective collaborative mechanisms at the right time have been highlighted in this white paper. DFMPro, CAMWorks and eDrawings together improve collaboration.

Addressing tooling and casting requirements at the design stage

This paper discusses various issues related to casting and tooling that can be addressed at the design stage to save valuable time and cost.